Everybody says that the chassis of M series, BMW, is pretty well and firmly, but all the references that people got are from official information or sponsored posts. How much actual differences are there? Take a look of M car from the point of view of the products we designed, essentially it's almost. However, if you study it carefully, you’ll find out that it's not easy only to keep his rigidity with lightweight design, the height of car is not only to lower the shock absorber, or adjusting the damping soft and hard makes you bored.

Even the I-beam or control arm and some other connecting bars are not cast iron but aluminum alloy material, it can't be boasted the structure will be stronger. Everything has many difficulties to a successful symbol of a brand, M-Gmbh.

There is no doubt with the producing of M car body, they definitely offered the top technology and skills. However, this is the basic condition to produce an excellent body for every famous brands, so it's hard to say how formidable they are.

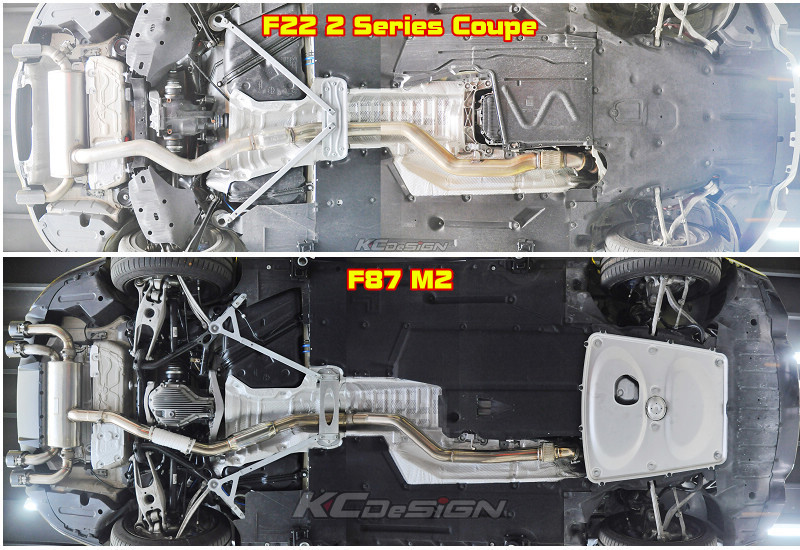

When we're devising the products of F87 M2, the body wheelbase of width and the lock point of I-beam are similar with F22.

However, the degree of chassis obedience is greatly different.

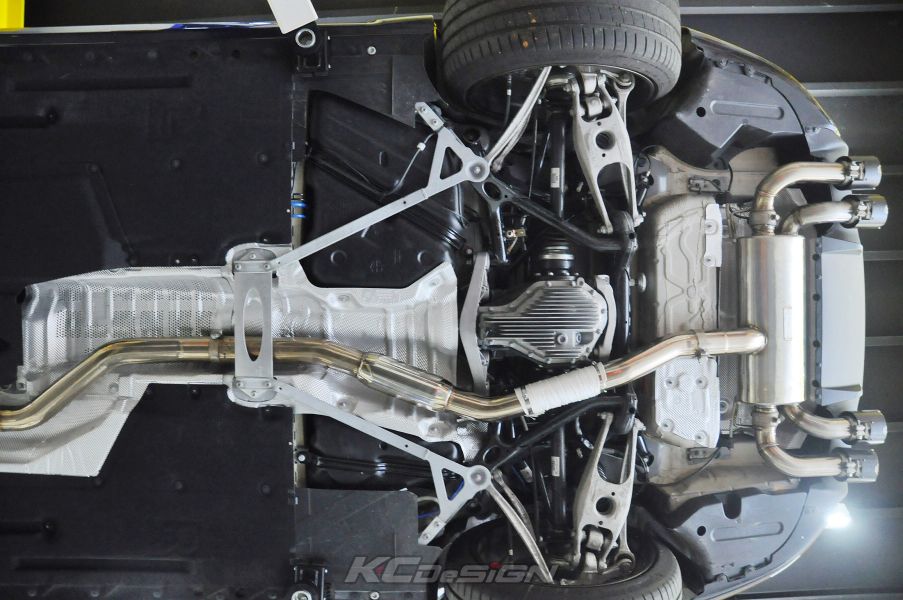

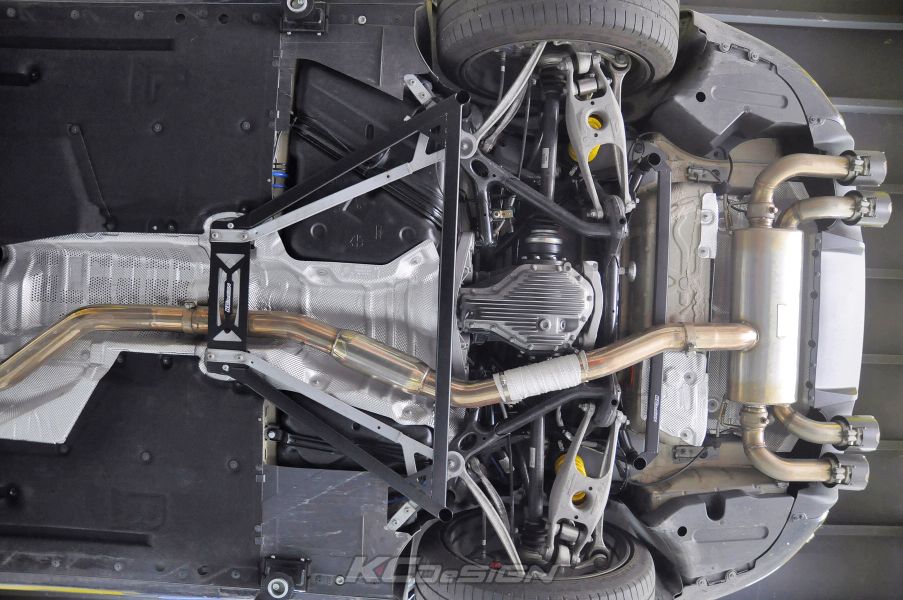

The height of deputy beam lock point of M chassis is quite high, so the deputy beam is closer to body than general F22.In other words, its center of gravity is quite low, it's better to send the message of the force feedback to driver, the deviation of height is almost two times.

For instance, if the deputy bean lock point of M2 is 3 cm, then F22's will be over 6 cm, we have detailed data but it's not available to offer.

The deputy beam is closer to body also means that the car's center of gravity is lower. The same situation happens on F80 M3 and F30, from the following photos, you can know the deviation of the lock point height of M chassis.

@lock point height of F2X/F3X

_007.jpg)

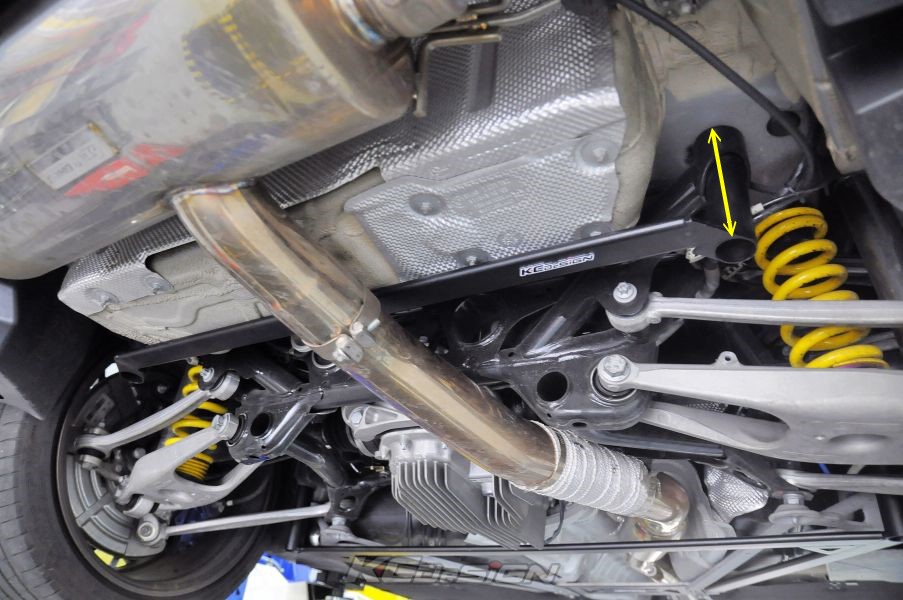

Hollow deputy beam has an effect of lightweight, and when it pair up fisheye strut link bar which is made of solid aluminum alloy to reduce the vibration of iron which is made by double layer press, then the whole dynamic reaction will be raised up.

The part of structural strengthening components, original manufacturer gives M car aluminum front I-beam and big area aluminum engine lower protection to enhance front bumper and the reaction of direction.

This point of F2X and F3X just could be enhanced by front lower bar (2 points), it can't achieve the strengthening as M car.

%E3%80%81%E5%89%8D%E5%BE%8C%E9%98%B2%E5%82%BE%E6%A1%BF026.jpg)

_010.jpg)

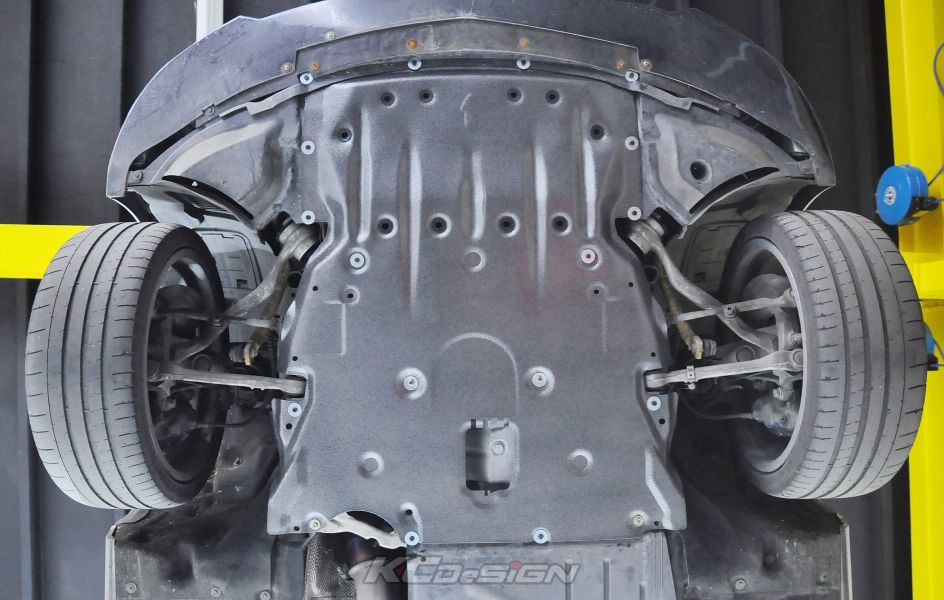

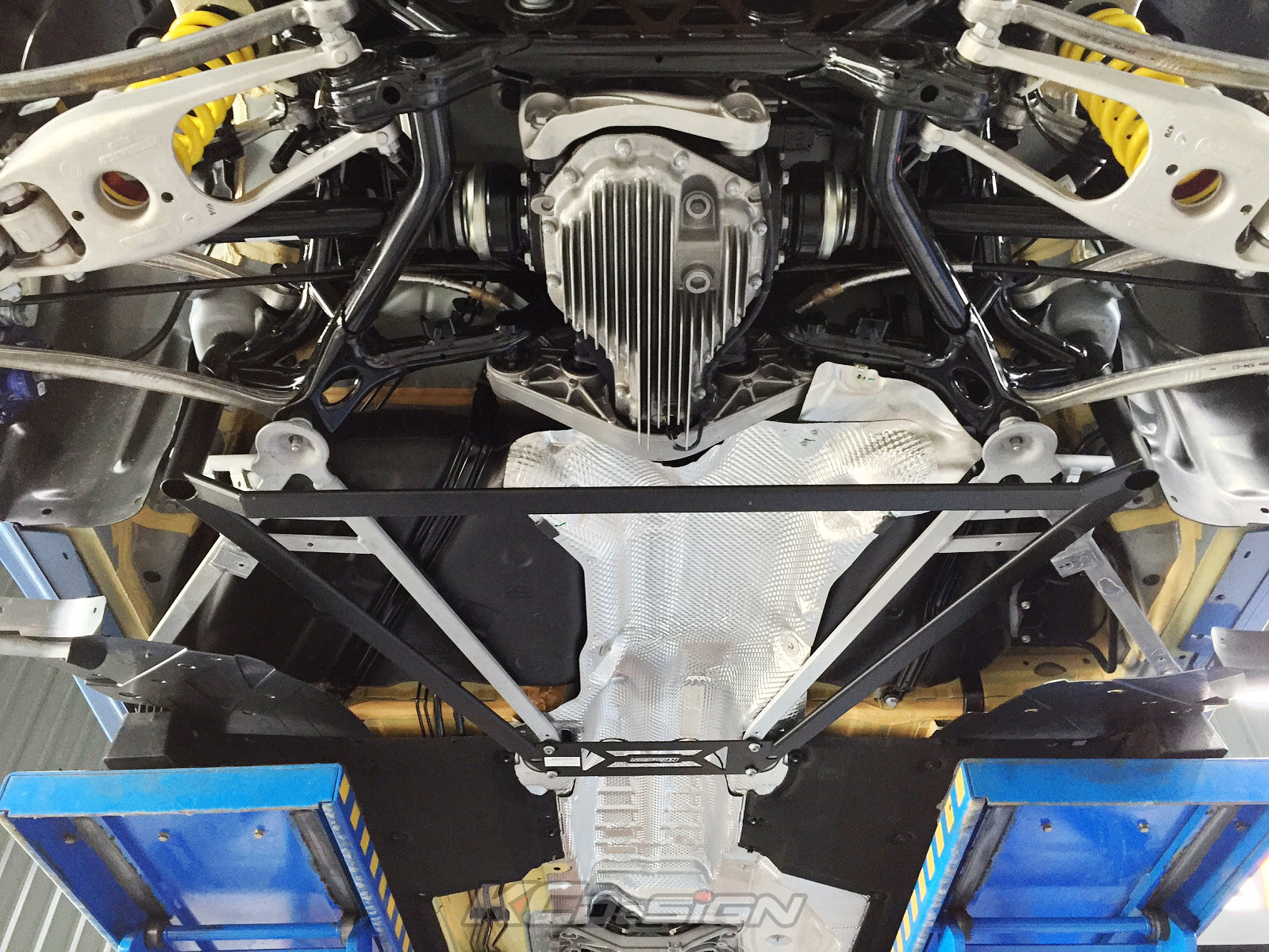

The following picture below is original structural component of M3 and M4.

The picture below is original structural component of F87 M2.

In the above picture, extending the lines to generate X-shape intersection is similar to use the X-shape structural component, which is counteracted by the whole weight of car body, therefore, the car is less likely to be pulled due to the power transmission, the problem of slippery or loss of grip would be avoided, it will maintain the comfort without losing the effect of manipulation.

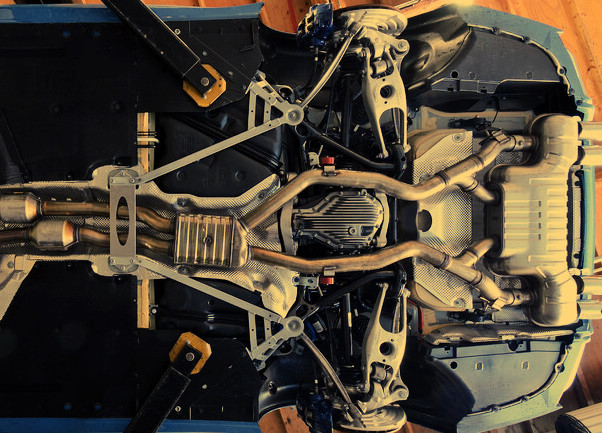

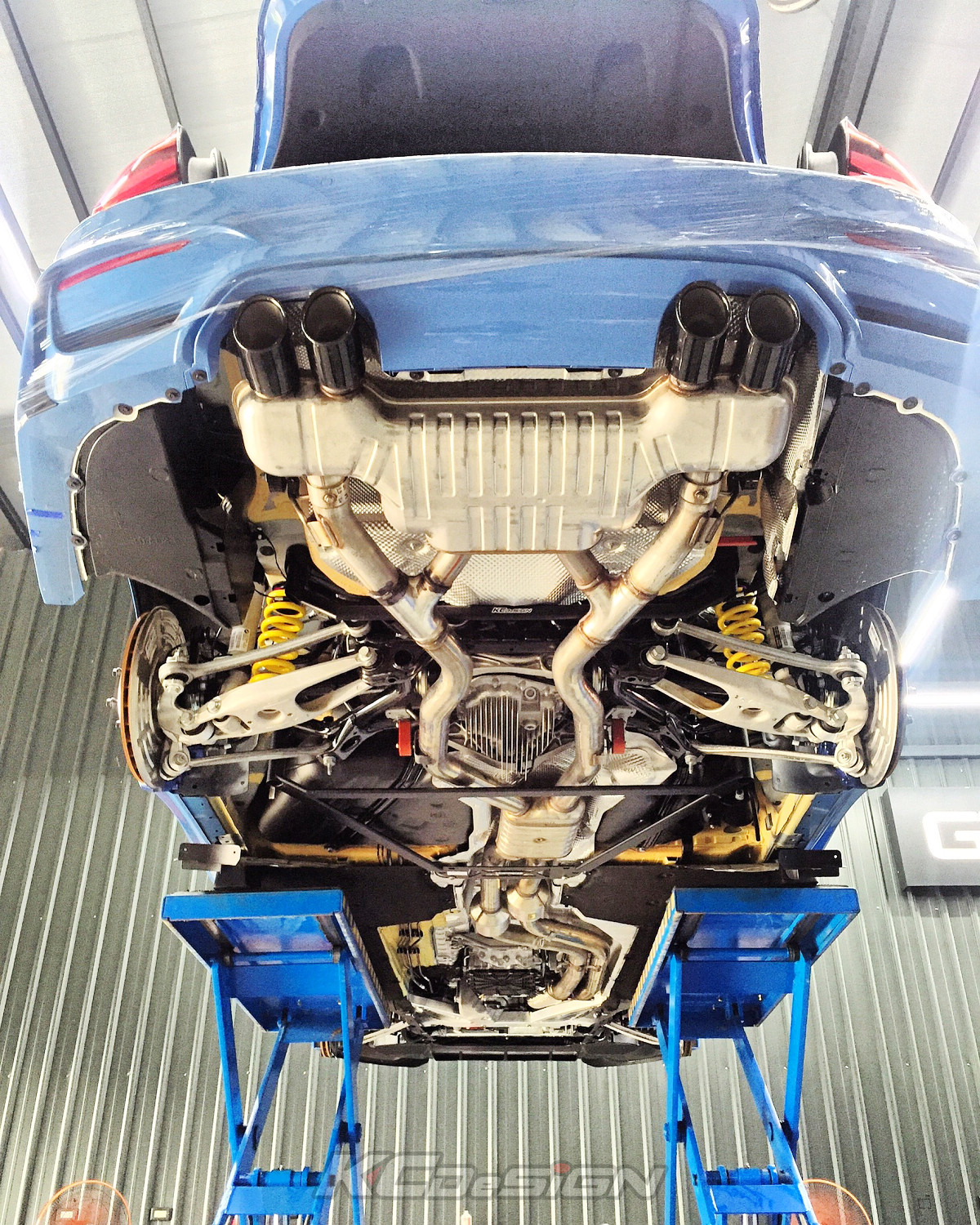

This is the rear lower bar (V Type) of general 2 coupe.

What the improvement plan of chassis optimization we focus on F22 2 coupe and M2 is to fill up the vacant part of the V shape which is in the middle.

- F22 2 coupe

_055.jpg)

- F87 M2 coupe

F80 M3 and F82 M4 are following the same way to optimize above.

- Rear lower bar (4 points)

- Rear lower bar (2 points)

- Front strut bar

.jpg)

This optimization plan is not only restraining the unsteady pulling due to high HP of rear-engine, but also raising absorbent of suspension damping to increase the traction. Therefore, the driver will feel it’s more stable and comfortable after installing all strengthening structure, not like what people thought, it’s hard and shaking.

All of the designed ideas are considered with driver and passenger, KCDesign is a brand which cares about the points of view from users.

If you like our products or want to know much more, you’re welcome to go to our distributor’s company or mine to look around.

Address of KCDesign: No.166-1, Ln. 222, Sanshu Rd., Sanxia Dist., New Taipei City 237, Taiwan (R.O.C.)